project management.

We provide project management services for all industrialization activities. Our project managers coordinate the activities and maintain close contact with the customer and development partners. This allows us to safeguard the optimal balance between quality, planning and budget.

design for assembly.

Early on in the design phase, we provide feedback on a new product’s manufacturability and testability. For this, we utilize our knowledge of and experience with the design principles of serial products. This ensures the product design is optimally suitable for stable and predictable serial production.

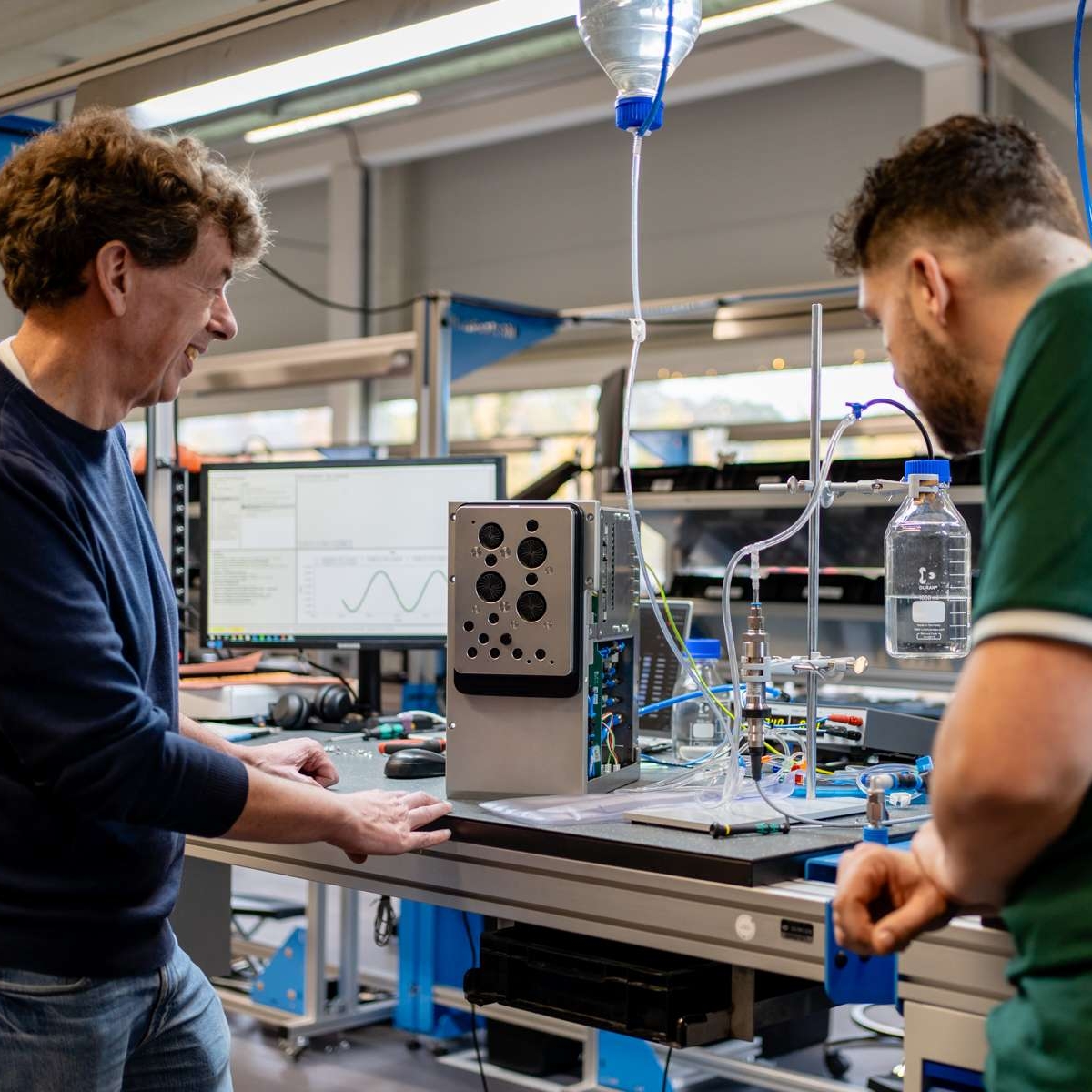

process development.

Concurrently with product development, we design and validate a matching production process. We analyze the process risks and implement measures to mitigate these risks to allow operators to produce in an effective, repeatable and safe manner.

test engineering.

Where necessary, we handle the development and validation of test tooling. We record test and qualification procedures, including instructions for troubleshooting and repairs. This approach ensures products can be tested and repaired in a reliable manner.

supply chain development.

We develop the supply chain for a new product. We make use of our existing suppliers and will select new suppliers if necessary, all to realize an suitable supply chain that can accommodate serial production.

prototyping.

We support the design team with the realization of prototypes. Based on our extensive practical experience, we provide feedback on the design’s manufacturability and the feasibility of the production process. If necessary, we can design and manufacture specific production tooling.