improving reproducibility.

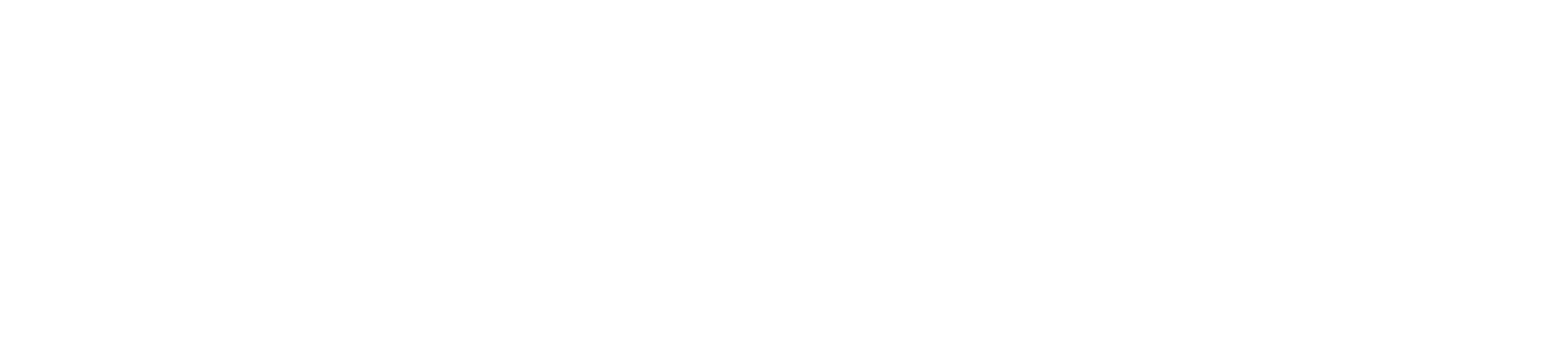

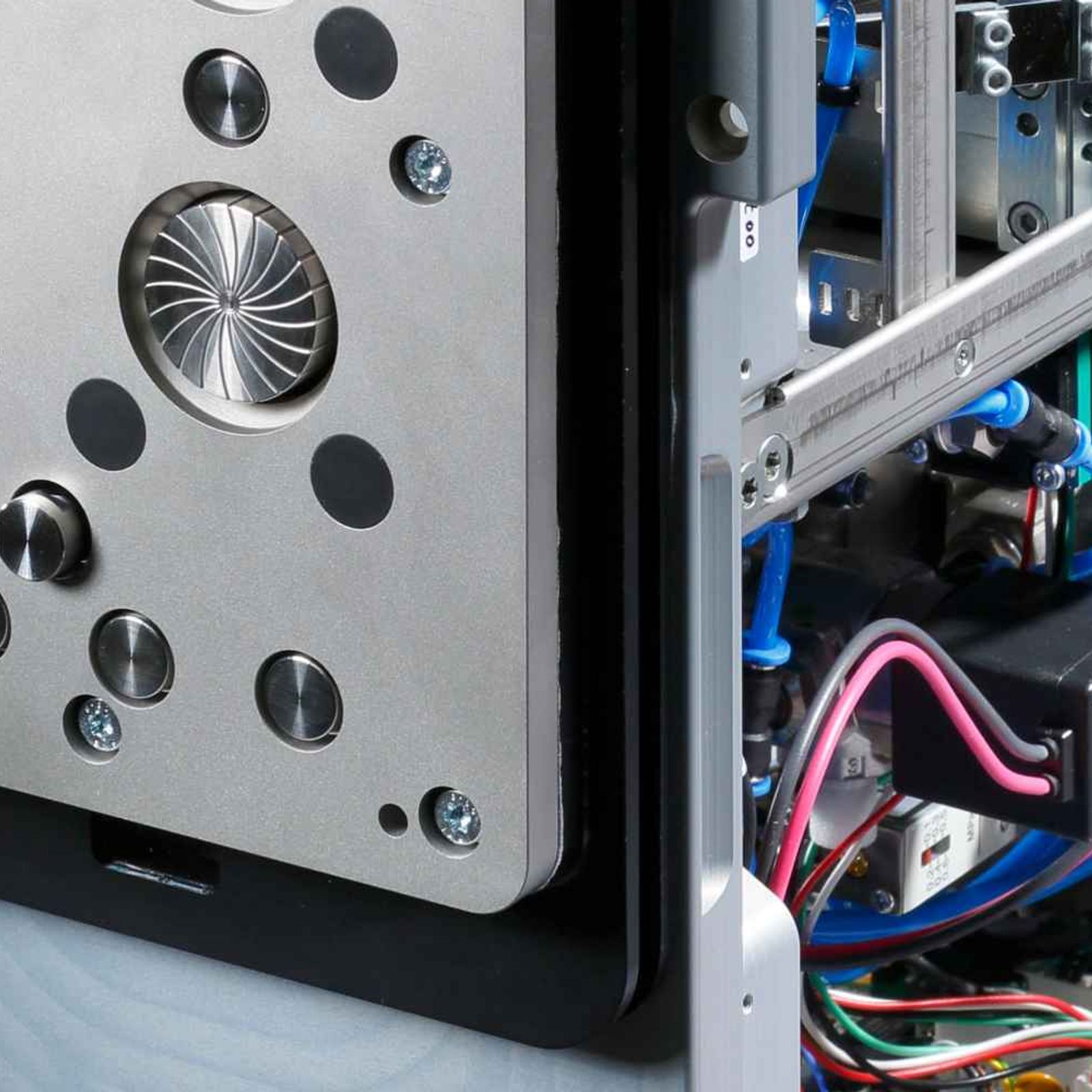

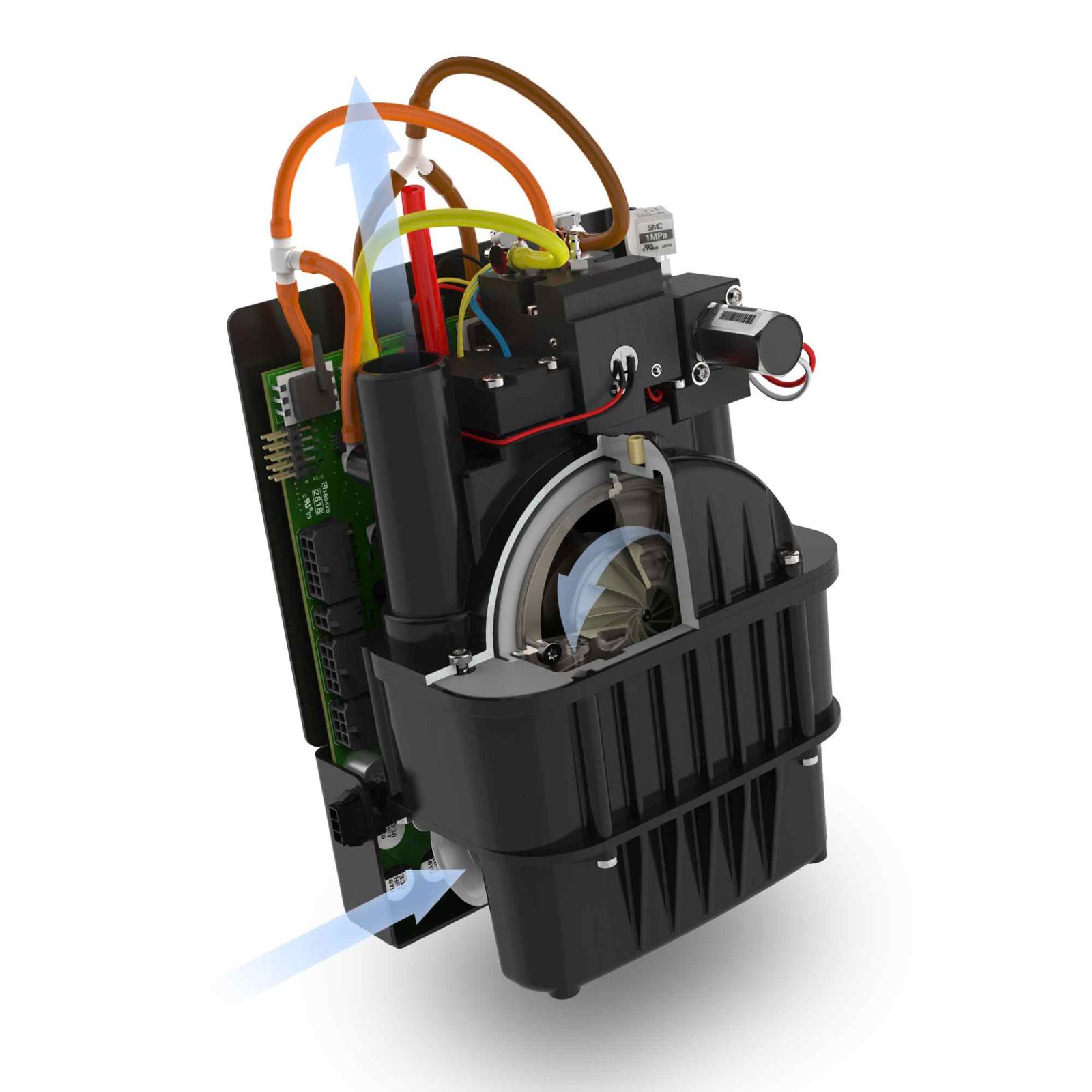

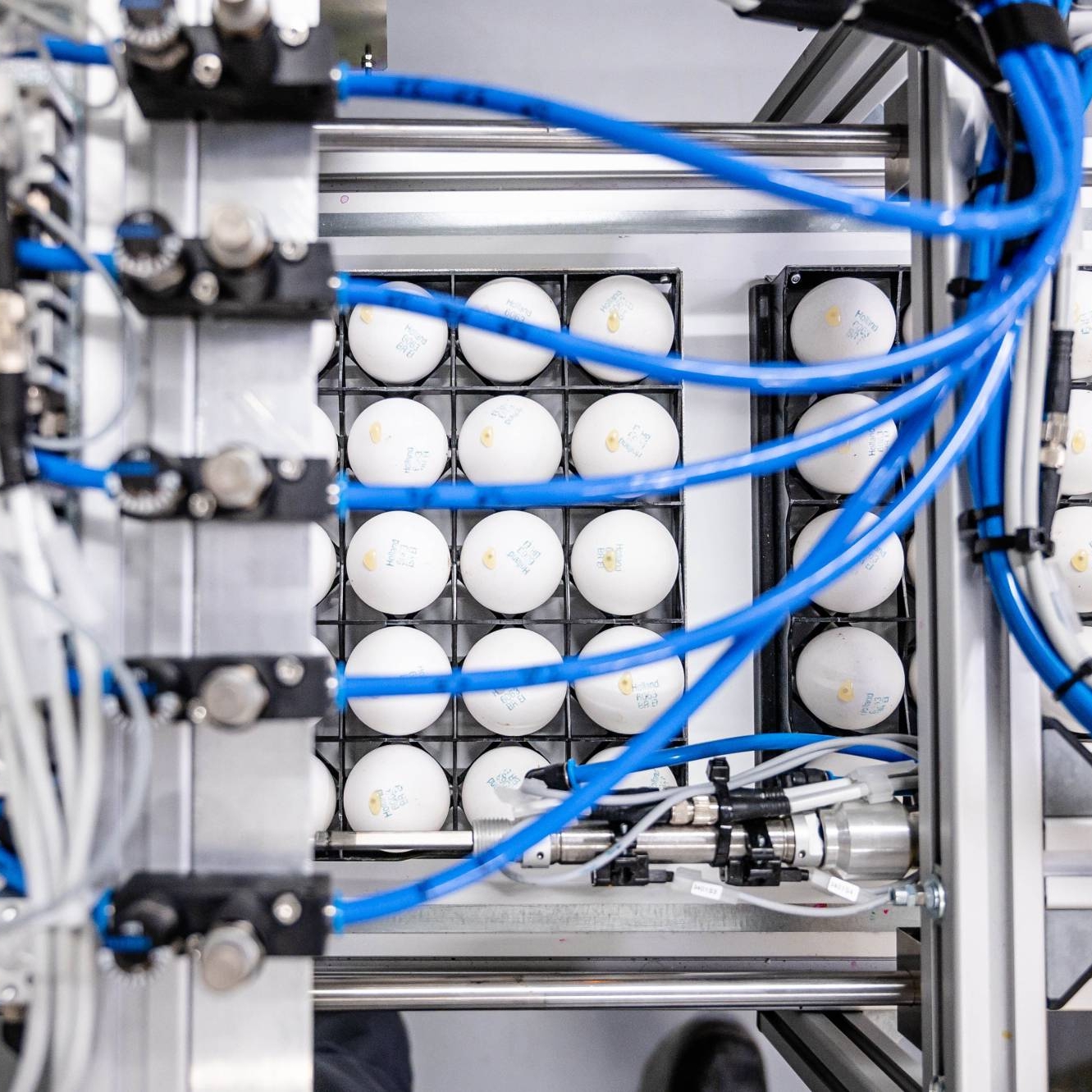

In Ovo developed a system for determining the sex of unhatched eggs: for this, the world’s fastest mass spectrometer takes a minuscule liquid sample from the egg. Demcon industrial systems has designed a machine that automates the entire process, which includes taking samples and handling the eggs. After delivery of the initial prototypes, Demcon began production of the system and implemented various changes to improve the (re)producibility of the system. We also suggested various simplifications to improve reproducibility during production.

highlights

- automation of sampling and handling

- further development and insutrialization

- experience with prototyping

- reproducibility and flow in production

improving the flow of production.

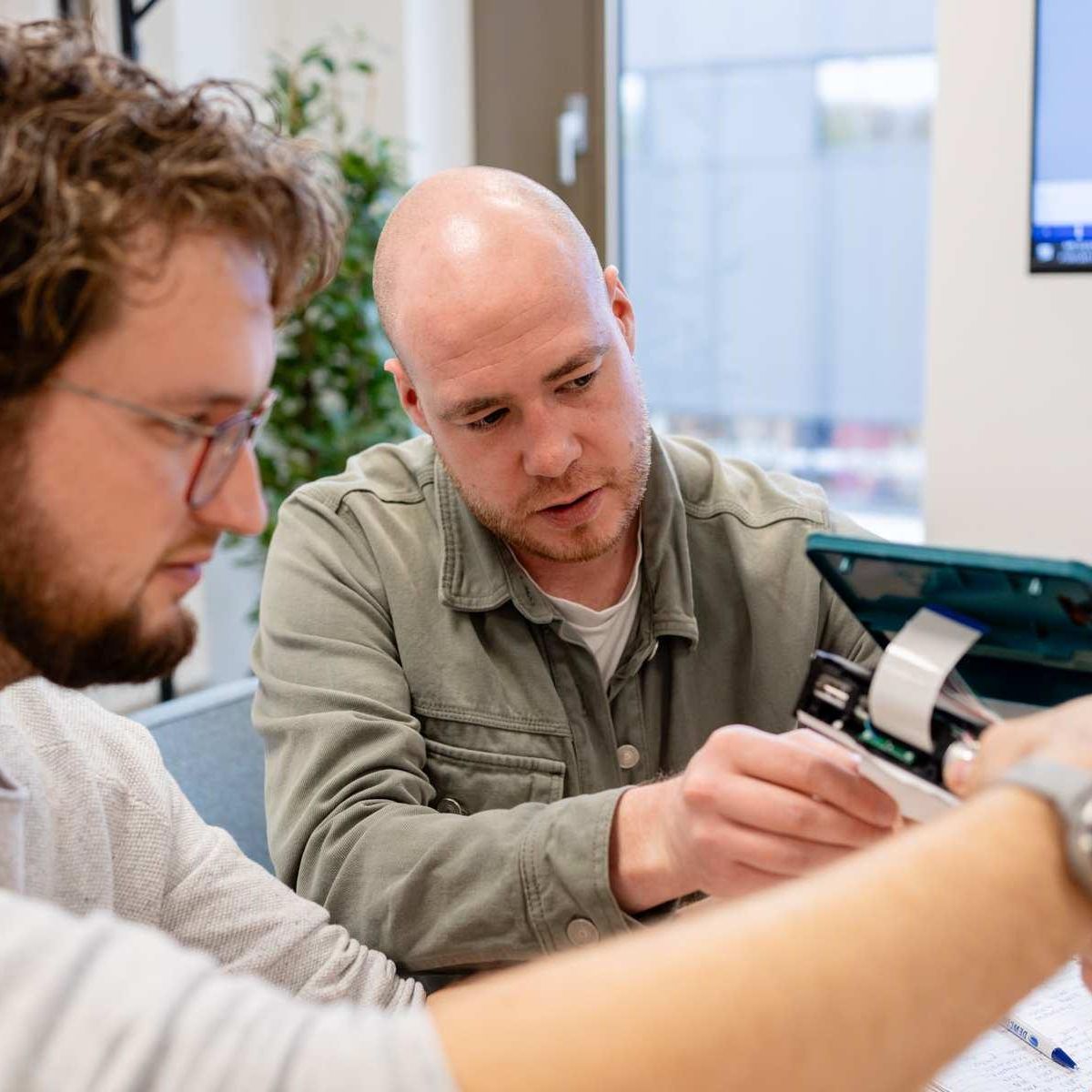

We have many years of experience with the structured production of innovative products and complex devices. In addition, we can handle the serial production of industrial machinery. This calls for a different approach with more space on the work floor and more flexibility. We collaborate closely with developers from In Ovo and other Demcon companies as part of a mixed team. We help them to further improve the machine’s functionality, while they assist us with industrialization. Our engineers and technicians possess a wealth of knowledge of and experience with prototyping. We also have the competences necessary for serial production. On the production floor, we do not rely on detailed instructions; instead, we take the liberty to modify the production design. At the same time, we are already thinking about the flow we can instill in the serial production. We do this by e.g. testing the various modules before they are integrated in the final machine.

"we love dynamism and structure."

As an industrialization engineer involved in serial machine development, I am always looking for ways to make improvements. We are flexible and will build an initial prototype while we are still working on product development.

I am close to the production floor and look at things from a design perspective. The design of the machines we build must be functional, people must be able to work with them. I share my knowledge of and experience with design-for-assembly with the design teams and I support the production process, e.g. with tooling. Our goal is to build every machine better and faster than the one before, while also adding structure to facilitate serial production.