consistent quality, variable quantities.

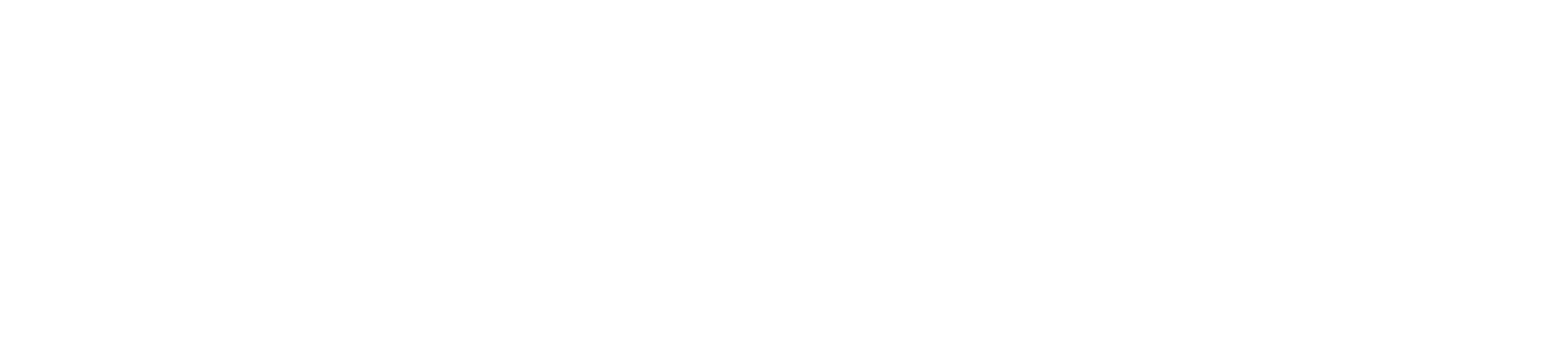

For its new EVA eye surgery system, DORC was looking for an effective solution for pumping sterile flushing liquid through the eye. Our colleagues from Demcon Life Science & Health developed an innovative concept and a product design, while we took care of the design’s industrialization and assisted DORC with testing and certification. During product development, we built the initial systems. Afterwards, we handled serial production of variable quantities with a consistent level of quality. We set up the assembly line in a way that allows us to scale up or down production depending on the client’s needs.

highlights

- product and production improvements

- flexible and lean assembly line

- one-piece flow

- design-for-assembly and production engineering

- quality testing for patient safety

- software-based validation

design-for-assembly, production engineering.

Together with DORC, we resolved various issues pertaining to the design, the quality of materials and the delivery of components to realize a better product design with improved manufacturability.

We set up the production line in a lean manner, with simple tools, the right order of activities and smart delivery of components. We combined product engineering with production engineering for an optimal design-for-assembly.

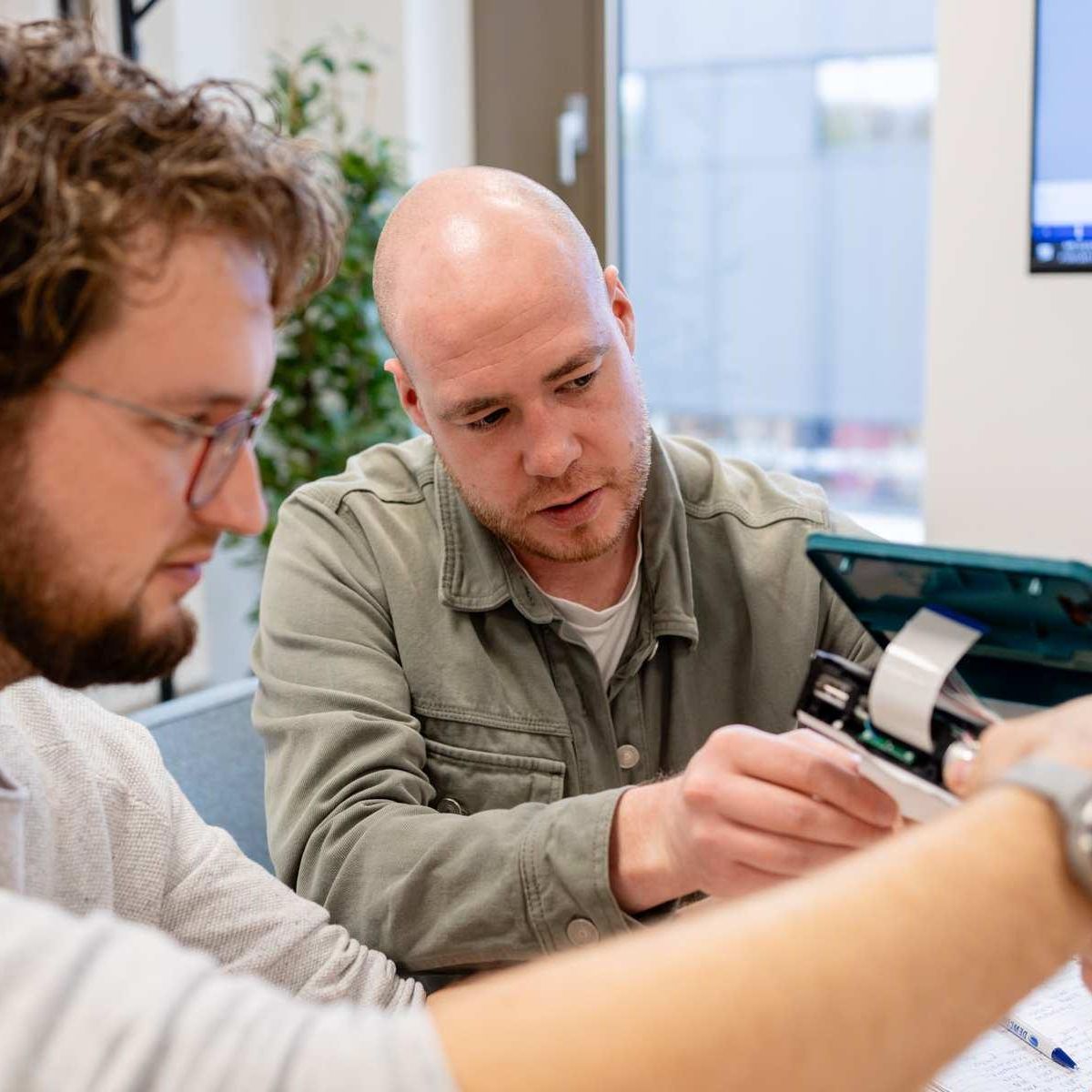

"the various techniques involved make producing the pumps even more interesting."

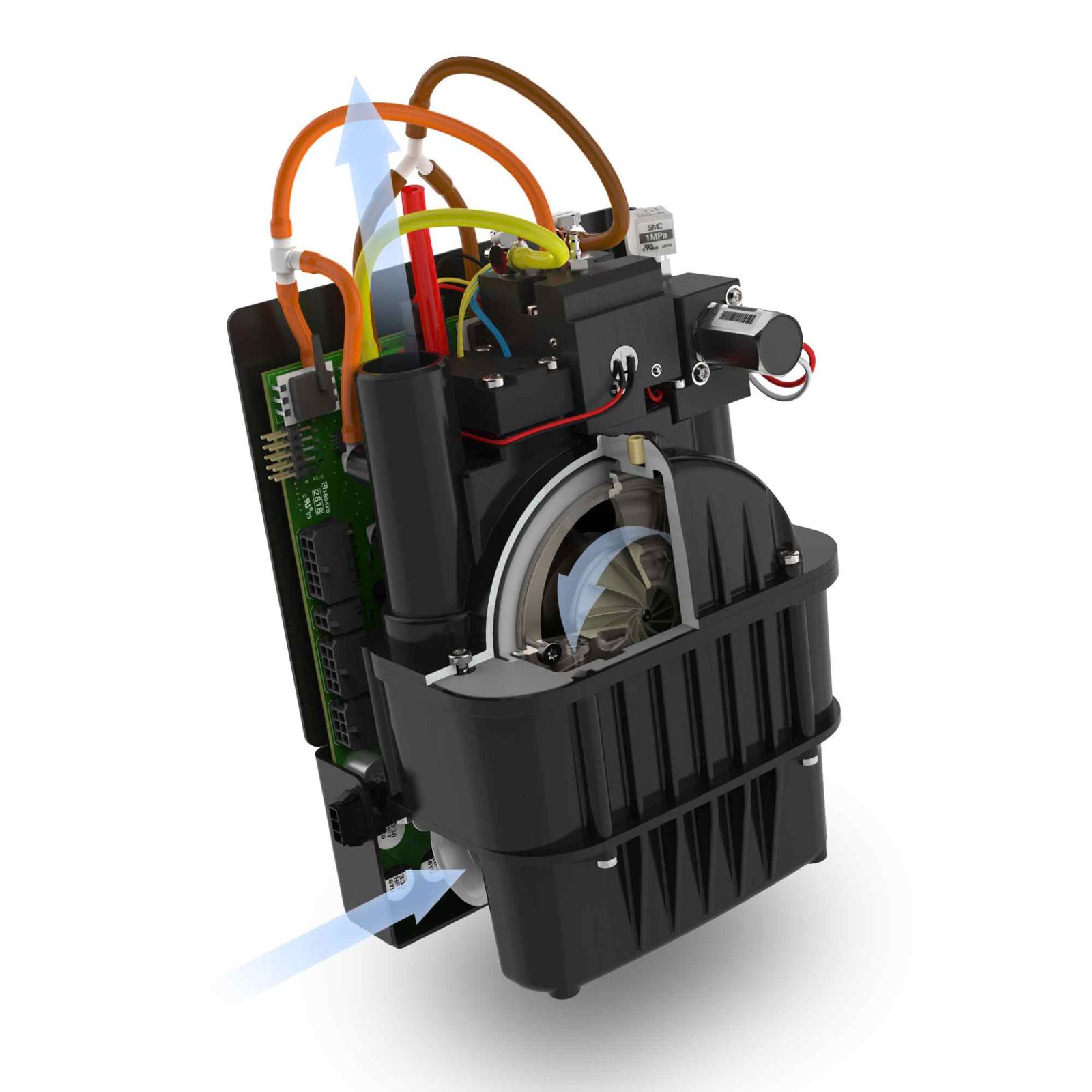

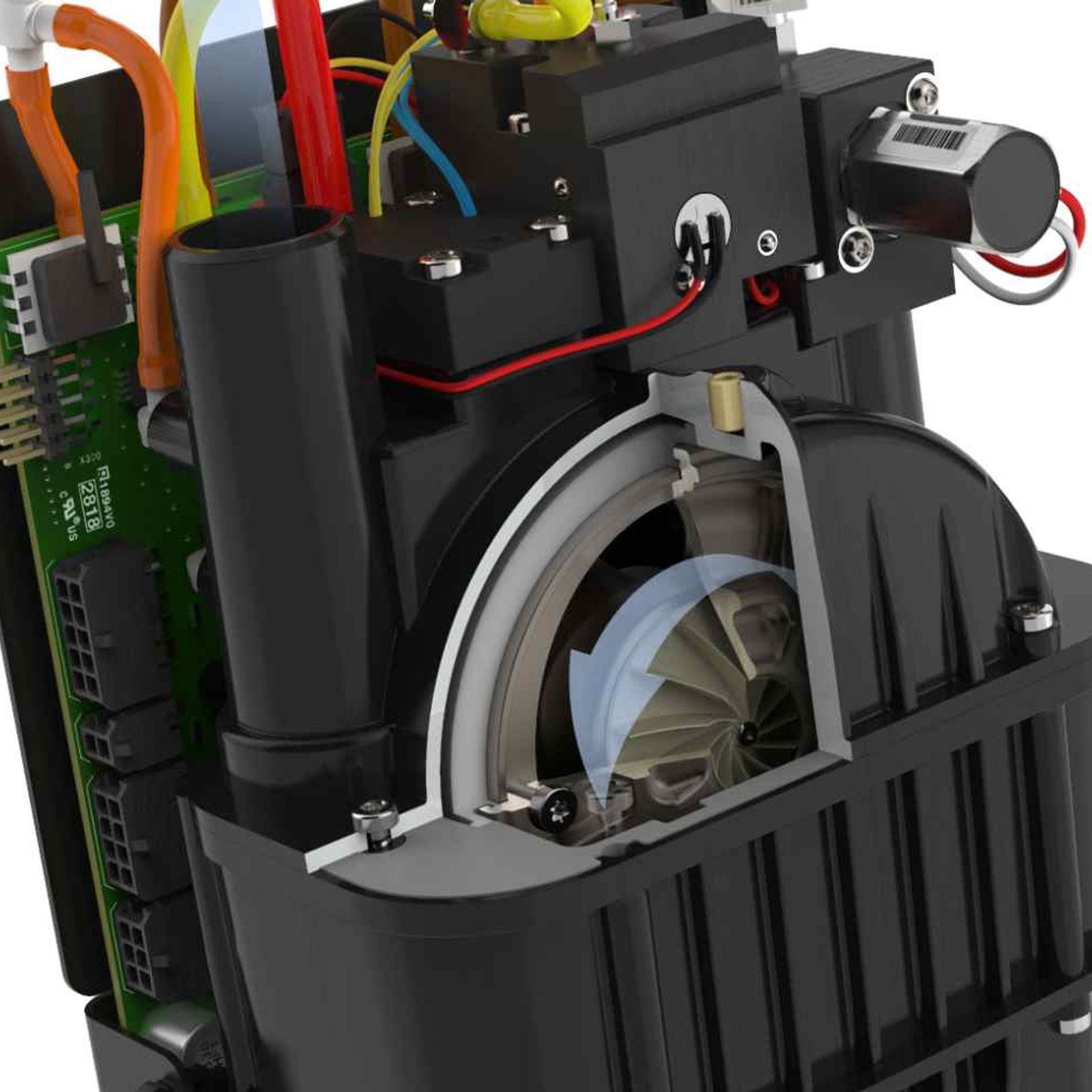

On the line where I work, we assemble and test pumps used in eye surgeries. These are highly complex machines. To build the pumps, we use magnetism, pneumatics, electronics, mechatronics and software. This diversity of techniques makes my work extra interesting. Testing is my favorite part, because it really lets you focus on the operation of the end product. I am primarily interested in the technology. The fact that we are producing medical products is the icing on the cake for me.