successful acquisition of medical production.

We have been a production partner for LABORIE…

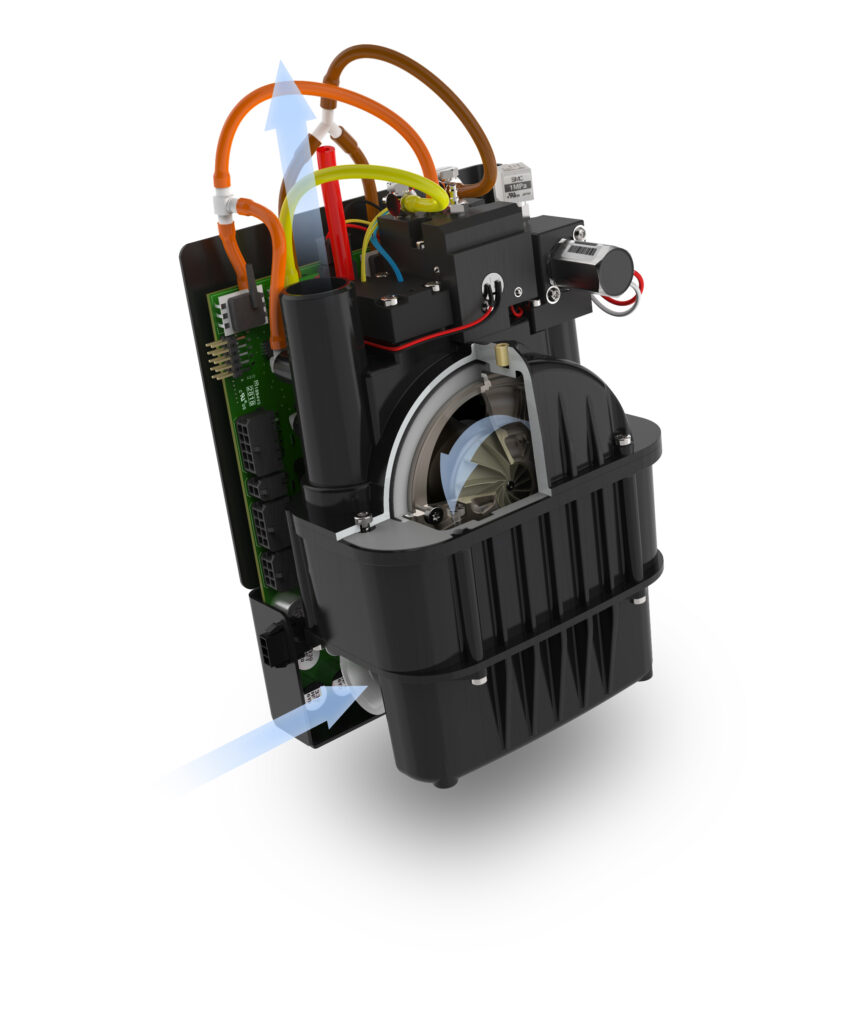

Read MoreFor many years now, we have been building high-quality ventilation modules for Demcon macawi respiratory systems. Together with the client, we have automated and optimized the production process. Our knowledge of and experience with production design allow us to rapidly scale up assembly capacity.

The unique ventilation module that Macawi has developed is suitable for any patient: from premature babies to adults. Such a crucial piece of equipment calls for careful assembly. For this, we rely on our knowledge of and experience with process engineering and medical certification. Our flexible production lines contain efficient assembly steps and comprehensive test procedures to guarantee a consistently high level of quality.

When we had to scale up our production during the COVID pandemic, we set up five additional assembly lines in record time. These were all copies of the original line, which we had thoroughly optimized over an extended period of time. We now utilize the resulting experience to assist Macawi with the development of a new product, with an even greater focus on costs and manufacturability.

My field of expertise ranges from medical to high-tech, which keeps things interesting. As a service & test engineer, I get involved early on in the design process. How can you make a device testable and how can you replace modules in the field? Developing the right tests requires a thorough understanding of both the process and the product itself. Overcoming technical challenges together with my colleagues motivates me. Finding ways to make a line stable for serial production. We are always looking for ways to implement or improve scalability. Without a doubt, the biggest challenge in that regard was the production of our ventilation modules during the COVID pandemic. We had to scale up production significantly in a very short time frame. We learned so much from that experience!